Contact

- No. 236, 3rd Main Road, Burma Colony, Perungudi Chennai – 600096, Tamil Nadu, India.

- hitendra@durapak.in

- +91 95822 52828

Brochures

Genesis Futura XL

A wide range of rotating ring stretch wrapping machines to wrap and stabilise loads on pallets with stretch film suitable for all industry sectors.

The Genesis Futura series of pallet stretch wrapping machines operate without sliding electrical contacts and feature the exclusive system that powers the pre-stretch driven rollers using batteries which are charged during machine pauses at pallet infeed and outfeed. This technical and highly innovative solution, in addition to eliminating all the typical problems of sliding contacts, also significantly reduces the overall machine weight and correctly balances the rotating masses.

This results in low electrical energy consumption, reduced maintenance, high reliability and long working life.

Furthermore, construction solutions have been adopted to minimise transport costs and installation time giving economic advantages for the end user.

Futura L max load 1450 x 1450 Maximum output capacity 55 Pallet/h depending on line speed and the total number of revolutions of film required.

DISTINGUISHING MARKS

ROTATION UNIT

The Rotating ring is a precision engineered component guaranteed to work at maximum speed. The smooth running of the ring assembly extends the working life of the parts in motion. Drive to the ring is created by a high resistance flat belt which is both very durable and extremely quiet in operation.

Rotation speed, acceleration and deceleration is controlled by a frequency inverter futher extending the working life of the equipment.

RING LIFT

Interconnected double chain arrangement mounted on a robust 4 column steel frame guarantees synchronous vertical movement of the ring assembly – Anti drop mechanisms are fitted as standard in the unlikely event of chain failure.

Ring lift/lowering speed is controlled by frequency inverter.

CLAMP AND CUT

Pneumatically driven clamp unit with hot wire film cut that also includes a film tail welding device as standard.

TOP SHEET COVER

TOP INSIDE device to cover the pallet with polyethylene film.

Film is dispensed using a patented system that unwinds the correct amount of film, optimising consumption and perfectly centring the top sheet over the pallet.

Film dispense and deposit occur without reducing machine production capacity.

“ROPING” DEVICE (OPTION)

Device that reduces the film strip into a “rope” to ensure more efficient load stabilisation by making the load and pallet a single homogenous unit.

Film is gathered from above or below in the single movement version while it is grouped at the centre in the dual cylinder version.

AUTOMATIC FILM REEL

The new automatic film reel change (ARC 2) uses two carriages located locally to the rotating ring and within the machine’s safety guards, once the reel is finished on the pre-stretch carriage, it automatically expels the core and fits a new reel. The reel change unit is then reloaded by an operator without stopping the machine.

This new device extends the duty cycle of the machine and results in higher production capacity.

The automatic reel change assembly can be provided as a single or double unit as required.

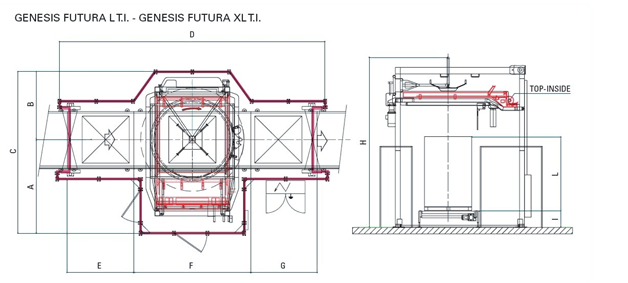

TECHNICAL SPECIFICATIONS

| TECHNICAL FEATURES | ||

| XL | XL T.I | |

| A | 3250 mm | 3200 mm |

| B | 2450 mm | 2450 mm |

| C | 5700 mm | 5650 mm |

| D | 9500 mm | 9500 mm |

| E | 2520 mm | 2520 mm |

| F | 4080 mm | 4080 mm |

| G | 2520 mm | 2520 mm |

| H | 5250 mm | 5250 mm |

| I | 500 mm | 500 mm |

| L | 2300 mm | 2300 mm |

| Pallet dimensions (*) | 1900×1900 mm | 1900×1900 mm |

| Ring speed | 30 Rpm | 30 Rpm |

| Max output capacity | 50 Pallet/h | 50 Pallet/h |

| Standard power supply | 400/50 V/Hz | 400/50 V/Hz |

| Power installed | 10.0 Kw | 11.0 Kw |

| Air pressure | 6±1 Bar | 6±1 Bar |

| Air consumption | 250 Nl/min | 350 Nl/min |

| (*) Possibility of stretch wrapping half and quarter pallet. | ||

DIMENSIONS

| STD Min pallet dimensions | 600 x 800 mm |

| STD Max pallet dimensions | 1000 x 1200 mm |

| STD Pallet Height | 2000 mm |

REEL CHANGE TECHNICAL DATA

- Reel change average speed – 45/60 sec.

- Quantity of film reel stored – n° 2 o.d. 250 mm

- Air consumption – 20nl/min. 6 atm.

- Total weight – kg.550

TECHNICAL DRAWINGS

Technical drawings of this machine are available ON REQUEST.