Interested in our Products?

Helix 4/2

Fully automatic pallet stretch wrapping machine with twin rotating arms for stretch wrapping palletized loads with polyethylene stretch film where very high production outputs are required or loads which require an above average amount of film to contain them effectively. Thanks to the twin rotating arm technology, the stretch wrapping process is performed on a static pallet thus eliminating any risk of product falling from the load during the wrapping process regardless the arm rotation speed.

Every pallet stretch wrapper from Robopac Sistemi can be fitted with a power pre stretch film delivery system which reduces film usage by up to 50% compared with hand wrapping and substantially increases load stability and presentation. Pre stretch ratio adjustable by changing gears or from the control panel. Helix machines represent the ideal solution for wrapping light, easily deformable, unstable loads and are present in most market segment fields.

Product Description

Due to the versatile construction of the rotary arm design the Helix range of stretch wrapping machines can be configured to wrap an outstanding range of products both larger and smaller than the standard pallet format.

Helix 4/2 is ideal for an output capacity up to 170 loads/h depending on line speed, and the total number of revolutions of film required.

DISTINGUISHING MARKS

ROTATION UNIT

Direct, geared drive to the arm rotation unit ensures maximum duty cycle and minimum backlash. Robust and tubular steel framework results in maximum operating reliability during heaviest work conditions.

Inverter control of the rotation arm produces smooth acceleration and deceleration safeguarding the integrity of the transmission train.

CARRIAGE LIFTING

Double chain system for maximum safety in any work condition.

OPTION – Up/down carriage speed controlled by inverter and continuously adjustable from control panel with possibility of changing the film overlap either on the upward or downward cycle.

CLAMP AND CUT

Scissor clamp with hot wire film cut (shown); optional press on welding unit avalable.

OPTION – Spring/ring clamp (ROBOPAC patent) with pulse hot wire film cut and film tail welding device (no contact with load).

TOP PLATEN UNIT

Positive pneumatically driven clamping device used with top cover systems (Top Inside/Outside) or for especially unstable/tall loads.

Also available with pantograph system (shown) for pallets with large height variation or installations with low ceiling height.

TOP SHEET COVER

Top sheet load covering devices.

In the TOP INSIDE version the top sheet is applied “mid cycle” to produce a waterproof wrap. Capacity of the machine is slightly reduced.

TOP OUTSIDE indicates the top sheet is applied outside the machine before wrapping giving a dustproof wrap. Capacity of the machine is unaltered.

ROPING DEVICE (OPTION)

Device that reduces the film strip into a “rope” to ensure more efficient load stabilisation by making the and pallet a single homogenous unit.

Film is gathered from above or below in the single movement version while it is grouped at the centre in the dual cylinder version.

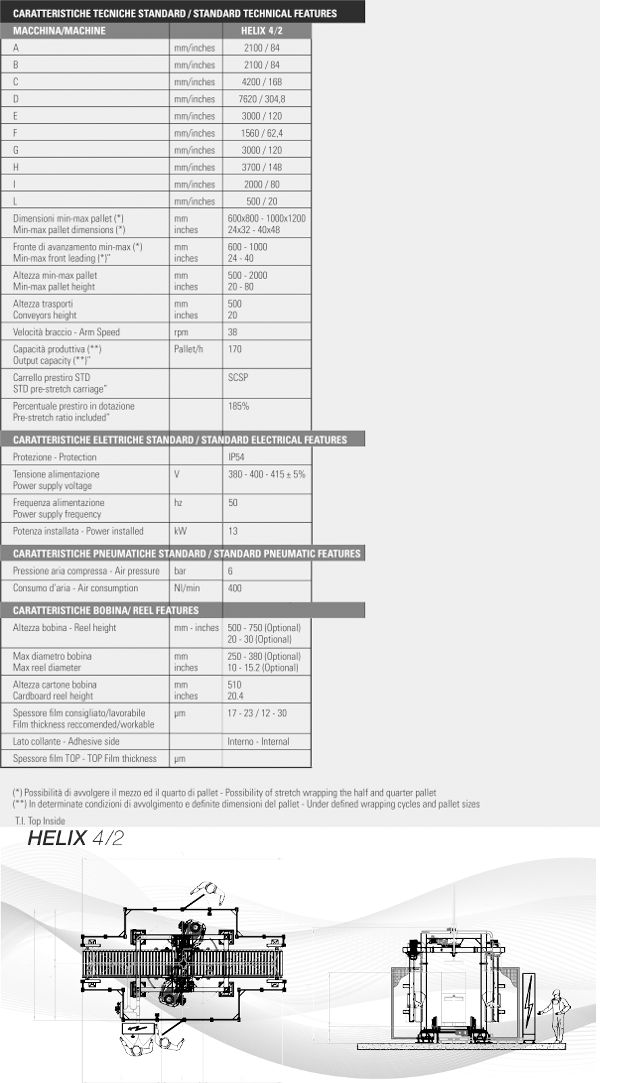

TECHNICAL SPECIFICATIONS

DIMENSIONS

| STD Min pallet dimensions | 600 x 800 mm |

| STD Max pallet dimensions | 800 x 1200 mm |

| STD Pallet Height | 2000 mm |

| Possibility of stretch wrapping half and quarter pallet. | |

STRETCH-FILM USABLE

| No. of reels | 2 |

| Film type | LLPD stretch |

| Height | 500 mm |

| Max external diameter | 250 mm |

| Min external diameter | 76 mm |

| Thickness | 23 µm |

| Weight | 16,5 kg |

SUITABLE FOR THE FOLLOWING PRODUCTS

- Paper products / tissues etc

- Full/empty bottles

- Full/empty cans

TECHNICAL DRAWINGS

Technical drawings of this machine are available ON REQUEST