Interested in our Products?

Pneumatic Strapping Tools

FEATURES

- Powerful tension, Maxi.350Kgs (3500N) for heavy duty plastic strapping jobs.

- Automatic tension , friction-weld and cut, no metal seals required.

- Air pressure manometer for on-site air supply monitoring.

- Adjustable tension force & sealing time for various strap specifications.

- Much smaller air hose at 1/4” I.D. for flexible operation without hose tangling.

- Alloyed Magnesium Aluminum mechanism ensures light weight and durable structure.

- Patented single motor structure reduces weight and lower maintenance cost.

- Modularized structure and reliable mechanism for easy and low cost maintenance.

- Ergonomic design and excellent weight distribution to reduce hand fatigue

- Built-in safety device for tension setting and prevent from scratching or breaking the strap.

- Easy “One-Step” straps inserting.

- User self-adjustable front & rear strap width guiders to assure perfect strap alignment.

- User changeable strap cutting blade and other wearing parts.

- Optional hanger to reduce operation fatigue.

Product Description

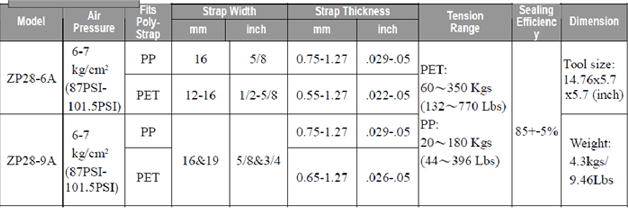

Specification

- Sealing time adjustment range : approximately 0-4.0 seconds.

- Air hose requirement: minimum 1/4” I.D. (Coupling, mountings and fittings must not fall below this )

- Air pressure requirement: minimum 6 bar ( 6 kg/cm² /87 PSI) up to 7 bar ( 7kg/cm² /101.5 PSI).

Remarks

- Air consumption, tension, sealing performances vary based on strap specification, quality, air pressure,set tensioning, sealing time and operation habit.

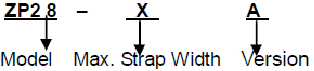

- Model number reference

- Strap width number 6: 12~16mm (1/2”~5/8”), strap width number 9: 16 & 19mm (5/8 “-& 3/4”).

- If PP strap under 0.75mm thickness is adopted, please reduce tension force. In result, tension speed will be slowed down proportionally by reduced air flow.

- Max. Strap thickness 1.27mm ( 0.05”) is allowed. However, a changeover of blade ( part no. 2885) is required.