Interested in our Products?

Skin Packing Machine

The DTB skin packing machine has been engineered and designed for trouble free, efficient operation. With its cantilevered film frame and film roll carrier, the DTB is ready for front loading. A balanced infrared reflector oven with industrial tubular elements provides the fastest film heating cycle available.

The film heating and frame cycles are automatically controlled by a solid state timer that is adjustable to precisely match your product, skin card, and film requirements for optimum results. Manual overrides for the automatic cycle permit the flexibility for samples, short runs, and intermixing products of varying heights.

The equipment is engineered to withstand rugged, continuous production use with a minimum of maintenance. The DTB is an excellent choice for energy efficiency and cost effectiveness. Years of production and engineering improvements have given the equipment a reputation for reliability, operating simplicity, and durability.

Product Description

Feature

- Display packing items on to card for point of sale display with high clarity Surlyn film.

- Can be used for transit skin packing using corrugated board and polythene based skin film.

- Boards can be manually cut to size by knife

- Sample skin packs can be produced using your products.

- Suitable for use with environmentally friendly “Peel Away” peelable skin pack board.

Available Models

| Model | DTB-390 | DTB-540 |

| Power Supply | 380V,50/60Hz,3PH,7.5Kw | 380V,50/60Hz,3PH,12Kw |

| Working surface | 390 X 540mm | 540 X 780mm |

| Packing speed | 50 ~ 60h | 50 ~ 60h |

| Widths of film | 450mm | 600mm |

| Machine Size (LXWXH) | 1500×600×1350mm | 1740×750×1350mm |

| Net Weight | 135Kg | 195Kg |

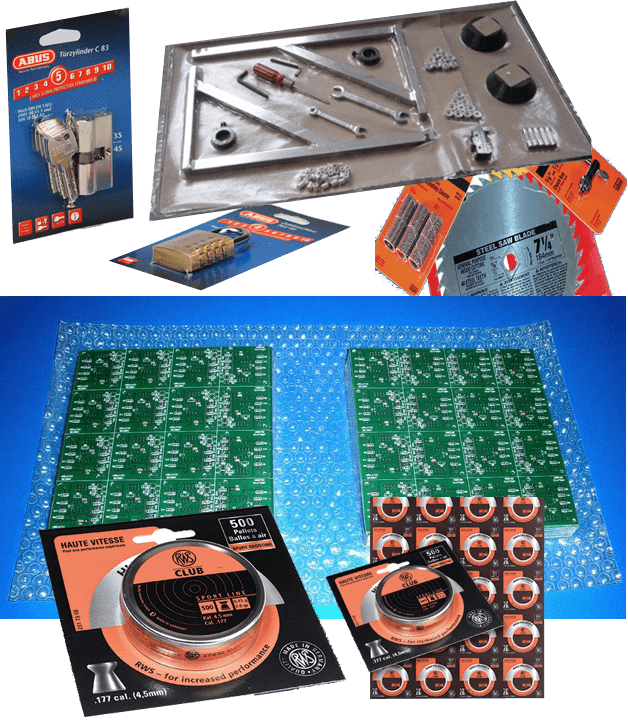

Samples