Have you witnessed products being flawlessly packaged with uncompromising quality? This is because of packaging machines. Packing machines have revolutionised FMCG and many other industries with efficient and consistent packaging solutions.

Are you ready to know more about these power-packed machines? Let’s discover 7 things to know about the packing machine and how it works in real-time.

Significance of packing machines in real-time

The packing machine is a marvellous industrial machine that improves the productivity of packing goods. From data-driven excellence to seamless integration, quality assurance, and predictive maintenance, it delivers the best results and packaging experience.

You can easily attain your ROI with the help of a new packaging machine. It makes your packaging line faster, smoother, and more efficient. Click here to know more about the best and latest packing machines available on the market today.

What is a Packaging Machine?

A packaging machine is a mechanical machine designed to efficiently pack various products into containers, such as bottles, bags, boxes, or cartons. They can fill, seal, label, cap, and package, often using sophisticated technology and sensors for accuracy and quality control.

7 Things To Know About The Packing Machines

#1 Real-time Data Collection

Today’s packing machines are fitted with sophisticated sensors and data collection devices that continuously monitor various packaging process parameters, including filling speed, weight precision, seal integrity, etc.

By collecting and analysing data in real-time, manufacturers can identify and address bottlenecks as they occur, reducing downtime and increasing overall efficiency.

#2 Automated Control Systems

One of the best things about packing machines is that they can run on their own. They have automatic control systems that can change things on the fly to ensure your packaging is consistent and accurate.

These systems use sensors to tell them what to do, and they’ll decide immediately, like changing the fill level or how long it’ll take to seal. This helps keep your product safe and your packaging looking good.

#3 Integration With Production Line

Packing machines are frequently part of a more extensive manufacturing process. Therefore, they need to be closely integrated with other machinery. This includes filling stations, labelling equipment, conveyor belts, etc.

Real-time communication between packing machines and other machinery is essential for synchronising and avoiding production bottlenecks.

#4 Quality Assurance

The importance of product quality cannot be overstated in the packaging sector. Packing machinery is vital in guaranteeing that each package conforms to the required specifications.

Through the implementation of real-time quality management systems, including vision and weight controls, defective products can be identified and eliminated from the production process in a timely manner, thus safeguarding product quality and minimising waste.

#5 Predictive Maintenance

Packing machines use predictive maintenance techniques to avoid unexpected breakdowns and expensive downtime. With real-time data analysis, packing machines can be monitored for wear and tear, and maintenance teams can schedule repairs or replacements prior to a critical failure. With proactive maintenance, packing machines can extend the life of their equipment and reduce operating costs.

#6 User-Friendly Interfaces

Packing machines can operate on their own, but they still need to be monitored and controlled by people. Manufacturers have realised how important it is for operators to have easy-to-use interfaces that let them see how the machine is doing in real-time and make changes as needed. This gives them a better understanding of the packaging process and lets them adjust settings for different products or packaging materials.

#7 Scalability and Flexibility

In the current market environment, it’s essential to be able to adjust to the ever-changing production needs. Packing machines, on the other hand, are designed with scalability and adaptability in mind.

| Did you know? The world’s fastest packing machine can package a mind-boggling 1,500 cartons per minute. That’s equivalent to packing more than 25 cartons every second. |

Primary Classification of Automatic Packaging Machines

The automatic packaging machines available on the market today can automate your packaging line. Three basic types of automatic packaging machines are available on the market.

Primary or secondary:

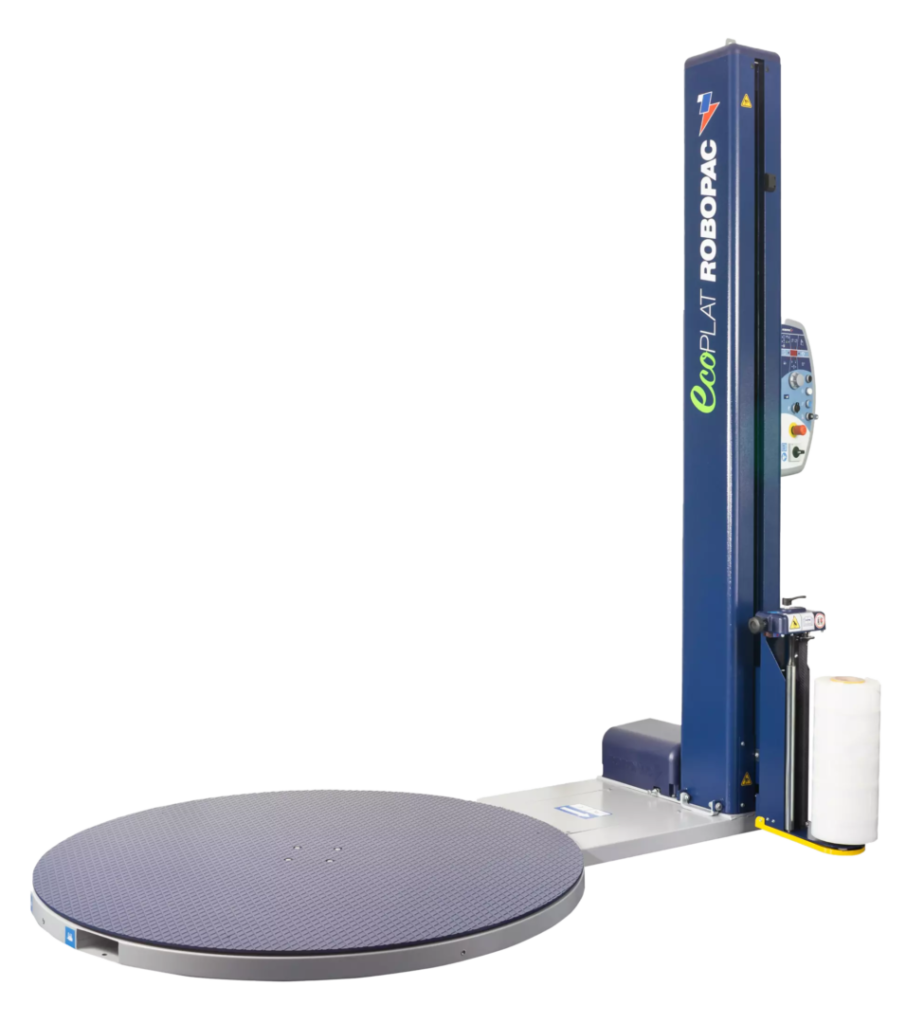

Primary or inner packaging is the packaging that comes into contact with the product. In contrast, secondary or outer packaging is the second layer of packaging and includes machinery such as wrapping machines, cartoning machines, box filling machines, shrink wrap machines, etc.

Single-function or multi-function:

Single-function packing machines perform only one task within the packing process. For example, they fill or seal. Multi-function packing machines perform multiple tasks.

Automatic or semi-automatic:

Multi-function machines tend to be fully automated and are usually more costly. However, you may want to consider semi-automatic packing machines if you have a tight budget or need to achieve a lower output.

| Did you know? The Guinness World Record for the most items packaged by a single machine in one minute is an astounding 458 items. This incredible achievement showcases the remarkable speed and precision that modern packing machines can achieve. |

Get High-Performing Packing Machine With Durapak

As technology advances, packing machines are expected to become more advanced and efficient. Durapak has established itself as a pioneer in the paper blank-filling market, providing a comprehensive portfolio of intelligent packaging services.

As one of the leading providers of protective packaging machines in the market, we provide a range of machine configurations, features, and add-ons for our paper forms that allow you to tailor your machinery to your packing needs and create the most effective production processes. Get your best packing machine with Durapak.

Experience Efficient Packing With The Packing Machine

Packing machines are versatile and dependable. They enable manufacturers to respond quickly to changing manufacturing requirements, maintain high product quality, and reduce downtime.

These powerful machines are the backbone for efficient, precise, and adaptable packaging processes. Businesses can harness the full potential of packing machines by understanding these 7 things to know about packing machines working in real-time.

| Also, you can get frequent updates on Durapak India Instagram page. |

Frequently Asked Questions (FAQs)

1. How does a packing machine work?

The packing machine is equipped with mechanical hands that can fold and pack the boxes. It also uses adhesive to stick the flaps of those boxes together and places the product inside the pack before it is sealed.

2. What are the objectives of the packaging machine?

- A few objectives of the packaging machine would be

- To achieve a range of weights or volumes

- To include functions such as date coding

- To maintain order and quality while packing

3. What is the method of packing?

The term method of packing refers to the process of packing products or items. The packing method changes based on the containers and materials used while packing. It involves shaping the formation of a corrugated box, placing the product into the box, and sealing it with adhesive.

4. What are the seven types of packaging?

The seven types of packing are

- Paperboard boxes

- Corrugated boxes

- Plastic boxes

- Rigid boxes

- Chipboard packaging

- Poly bags

- Foil sealed bags.

5. What is package shape?

The shape of your packaging is an integral component of your product design. It safeguards your product and is highly customisable. The shape of your packaging helps to differentiate your product and make it stand out from the crowd. This is significant, as it is estimated that 70% of consumers form brand impressions solely based on packaging.